How safe is safe enough?

Safety is always a priority but the question is how safe is safe enough? The story for today centers on your risk matrix. The reality is that our world depends on risky processes to function. From the gasoline in the vehicles we drive to the fertilizers and chemicals that help to grow our food and produce the articles of everyday life, risk is inevitable.

It Comes From the Top

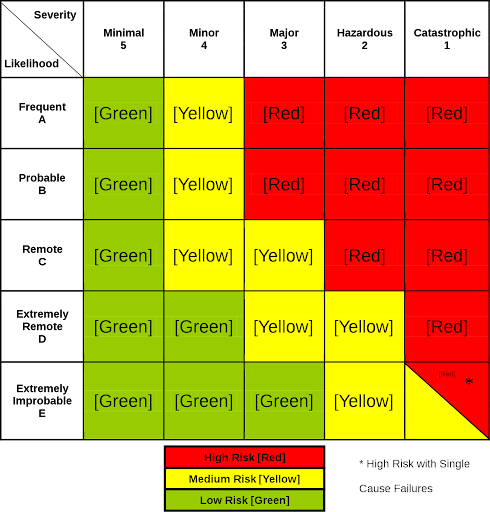

It is important for organizations to accurately determine their risk acceptance criteria and share that information across the company. Decision-making at all levels needs to be guided by this one view of how to manage risk in operations. It will influence the approach taken by engineering teams in the design of facilities, and it will be a main factor in how they build, maintain, and operate their equipment. The most common tool for this is a risk matrix.

What is a Risk Matrix?

A risk matrix is a visual representation of the intersection between the likelihood of an unwanted event and its severity. Where the likelihood is low and the severity is low it is easy to accept the risk. Where the severity is high and the likelihood is high it is similarly clear that a different approach may be required. The challenge comes in establishing definitions and guidance that are in line with leadership and organization philosophy.

Putting it in Practice: Scenarios A & B

Company A is focused on safety and rightly so! The senior leadership sets the tolerable risk very low. This decision influences all of the activities of the organization from determining minimum staffing levels to equipment selection, and project planning. The facilities are spotless and are designed with complex automation to minimize or eliminate every potentially risky scenario.

All is going well until it comes time to maintain this incredibly complicated operation! The equipment that was purchased to make the operations as safe as possible cannot be properly maintained and ends up becoming a liability. Regrettably, the investments made in the safest possible mode of operation result in too much overhead and the company can no longer remain viable.

Company B is the opposite, they believe nothing bad can ever happen to them and accept much more risk than is higher than their industry peers. They are plagued by incidents and regulatory fines, and their even worse, the facilities experience frequent outages due to persistent fires, accidents, and other impacts. This company is no longer viable either, but because of the contrasting impacts of a highly risk business.

These are extreme examples but they illustrate the determination of ‘safe’ is not as simple as it sounds. There are industry best practices and many organizations follow their peers in designing their risk matrix but that’s not always right either. It’s important that you calibrate your company’s matrix to what makes sense for your industry, type of operations, and your organization’s culture. The risk matrix also needs to be revisited on a regular basis, to ensure that you are keeping up with regulatory and other business changes.

You can read more on this topic in the Center for Chemical Process Safety’s “Guidelines for Developing Quantitative Safety Risk Criteria” found here: https://www.aiche.org/resources/publications/books/guidelines-developing-quantitative-safety-risk-criteria

For more support contact us at RskLess! Our experts will help to guide you through best practices ensuring your approach is reflective of what is right for your business. We’re here to help you be safer than yesterday.